What’s ESPOR®

ESPOR® Air-Permeable Casting Technology

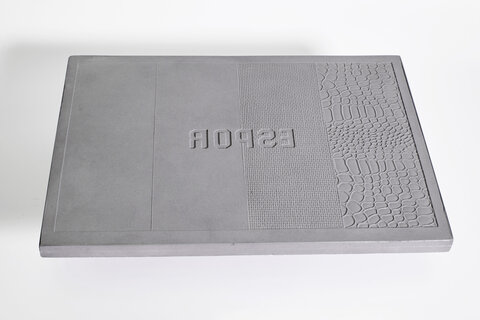

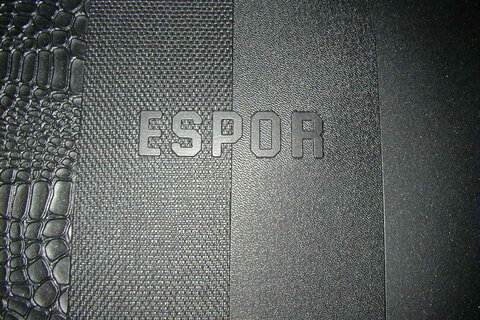

ESPOR® air-permeable casting technology is a patented combination of porous materials and process developed by Portec. The moulds will be manufactured according to your patterns.

ESPOR® technology is used to manufacture customer specific micro-porous air-permeable products for numerous industrial applications where homogenous air-permeability is required. Over the last decades we have been producing many different ESPOR® moulds for various industries.

ESPOR® moulds combine the economic benefits of classic thermoforming technology with the optical advantages of modern moulded skin and laminating technologies.

ESPOR® moulds to transfer the grain structure onto the foil during the thermoforming process without grain stretching.

Our ESPOR® technology is very well suited for parts with a complex-, smooth surface or with a fine structure (e.g. IMG-moulds).

ESPOR® moulds are a reasonable priced alternative if you don’t want to invest in expensive moulds (nickel, nickel-copper tools or milled moulds in general). Beside the price advantage are complex production moulds often needed in a relatively short period of time.

With our ESPOR® casting technology is it possible to produce moulds a lot faster, thus are your parts faster available.

ESPOR® moulds: The efficient way to optimally grained surfaces.